Lives, research, and expensive equipment are at stake when it comes to fire sprinklers in cleanrooms

Dust, grime, and bacteria can gather on fire sprinklers, out of sight and often out of reach during a typical cleaning. The Joint Commission, a nonprofit organization that accredits and certifies tens of thousands of hospitals in the United States, penalized nearly two in five hospitals for dirty or damaged fire sprinkler heads in the first six months of 2017. And in the immaculate environments used by the makers of sensitive microelectronics and healthcare products – where cleanliness is measured by the particle – the fight against contamination enlists every process, fixture, and feature, including fire sprinklers in cleanrooms.

To see how certain concealed fire sprinklers are an affordable defense against multi-million-dollar contamination in ultra-clean environments, read on.

How clean is clean?

Cleanrooms are controlled environments used in industries where even microscopic levels of dust, living organisms, particles, or other contaminants could ruin products or research or harm people.

A dust particle on the end of a pencil’s eraser is as small as a ladybug in a 50,000-person stadium (maybe smaller). How many would you find in the world’s most rigorously-made cleanrooms?

None.

In these environments, every decision and aspect of design counts. Cleanliness isn’t just about the walls, floors, and ceilings, but also the outlet covers, the kinds of pen and paper used, and even the cleanliness of nearby rooms.

But cleanrooms, like any other industrial space, aren’t exempt from fire safety. And at a cost of up to $1,500 per square foot to construct some hard-walled cleanrooms, it’s critical to have a fire sprinkler system that’s both functional and helps keep the space contaminant-free.

The cost of stray particles

While the costs of cleanroom construction are high, the cost of contamination is often much higher.

Cleanrooms are classified by the International Standards Organization (ISO) according to the level of cleanliness required.

For example, a Class 2 space might be ideal for photolithography — a process used in circuit boards and other small electronics — because it allows for no more than a few dust-sized particles in every square meter of air. In contrast, a Class 8 space might only serve as the buffer between those zones and the outside world, providing some filtration but still leaving tens of millions of large particles airborne.

If these standards seem rigorous, it’s because the cost of error can be enormous. For pharmaceutical companies, failing to observe these standards can lead to fines and product recalls. A fungus found in drugs sold by the New England Compounding Center caused hundreds of brain infections in 19 states, including nearly 70 fatal incidents. And in 2006, Apple recalled almost two million batteries. Microscopic metal particles led to electronic failures, setting off a chemical chain reaction that made batteries overheat and, in some instances, catch fire. The recall cost the company as much as $258 million.

Sanitary design and fire sprinklers in cleanrooms

Cleanrooms and other environments where cleanliness is critical are constructed from materials that are durable, easily cleaned, abrasion-resistant, and can withstand harsh chemicals used to eliminate contamination. Typically, that includes materials like stainless steel, anodized aluminum, and polymer coatings.

To limit contamination from outside spaces, the cleanroom structure must be airtight. Sprinkler heads should intrude as little as possible into sanitary spaces and minimize the potential for leaks. Openings are required for light fixtures, piping, wiring, and sprinkler heads, but each should be sealed, and every mechanism should be suitable for frequent cleaning.

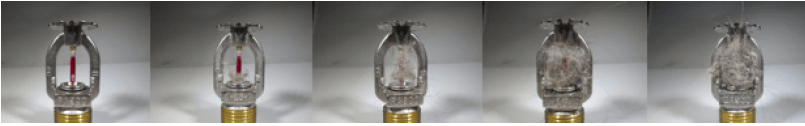

Regularly cleaning the most common sprinkler heads — such as the pendent head pictured top-right below — would be a problem.

In an earlier blog, QRFS explained the right way to clean a fire sprinkler head using pressurized air and/or a vacuum. To prevent damage to the head and avoid accidentally activating the sprinkler, it’s critical that the head not be touched.

While this might work well in an office or a warehouse, every surface in a cleanroom environment likely requires chemical cleansing on a regular basis. For ultra-sanitary spaces, the key is choosing a sprinkler that won’t discharge or get damaged when you clean it.

Cleanroom sprinkler covers

Concealed head sprinklers simply hide the sprinkler head behind a cover plate.

Just like the sprinkler itself, the cover plate is designed to detach at a specified temperature, allowing the head beneath to deploy and extinguish the fire. Concealed fire sprinklers have a smooth surface, providing the same level of fire safety but with a surface that gathers less dust and cleans more easily.

If you’ve already got cover plates in your sanitary space or cleanroom, remember: each concealed fire sprinkler has only one replacement cover plate. If you’re looking to replace yours, please click on this guide to help you find the right one.

At QRFS, we offer replacement cleanroom cover plates or air and dust seals for Reliable, Tyco, Victaulic, and Viking concealed sprinklers.

These cover plates provide a simple, cost-effective, and time-saving solution to the problem of dirty sprinkler heads in ultra-sanitary spaces.

Click here to view our cleanroom cover plates and air and dust seals.

If you have any questions about cleanroom cover plates or need an item that’s not on our website, contact ORFS at 888.361.6662 or support@qrfs.com.

This blog was originally posted at QRFS.com/blog. If this article helped you, check us out at Facebook.com/QuickResponseFireSupply or on Twitter @QuickResponseFS.

Sprinklers are highly reliable devices that are activated by heat. They will only go off if there is a fire which increases the heat beyond the sprinkler trigger point.

Above article is awesome and contains nice information. please keep it up.

Dear Sirs,

I work in a pharmaceutical company – HOVIONE. Do these type of concealed sprinklers work with foam or only when supplied with water?

Kind regards, Álvaro

The sprinklers referenced in this article are traditional water-spraying fire sprinklers.

Dear Sirs,

I work in a hospital. I did not see “fire sprinklers” in the USP797 and USP800. Is there any federal regulation/act about the fire sprinklers in a cleaning room?

MingerDer — the main rules from most industries point to and reflect NFPA and ICC model codes that have been adopted as legally enforceable state codes, which reference NFPA standards for fire sprinkler installation and maintenance. Federally, the Department of Health and Human Services and Joint Commission specify hospital accreditation agencies and set standards involving fire protection and life safety, while also referencing NFPA.